Luna.Technology Used for Structural Health Monitoring at Cut River Bridge

The Cut River Bridge along U.S. Route 2 in Michigan’s Upper Peninsula was instrumented with Luna technology as a part of a research project to study the feasibility of a structural health monitoring system (SHMS) for monitoring the structural behavior, evaluating safety, mobility, asset management and planning applications using remote sensors.

Cut River Bridge的试点项目是一个模型,可以在密歇根州的其他桥梁位置使用,并且从该项目中吸取的经验教训将帮助MDOT在其他桥梁站在其他桥梁站点上的SPMS实现。

利用SHMS,可以监测关键桥构件中的应力,并且可以在结构构件的需求和容量之间进行比较。该监测用作任何结构成员的任何可能过度关注的预警系统。这与断裂临界结构尤其重要,因为在发生故障之前可能没有给出没有视觉警告的临界结构。当超越安全的阈值应变值时,系统可以设计成警告MDOT和工作人员对桥梁的潜在问题进行响应。SHM可以有助于确定结构构件之间的负载分布,这可以是截面损耗的指示和结构的刚度变化。随着结构构件中力的准确测量,可以更好地估计结构继续安全地承载交通的能力。这将有助于MDOT规划未来的任何维修并评估与桥接相关的任何风险。可以通过比较改装之前和之后的应变值来监测维修的有效性,这也将有助于估计剩余的使用寿命。

由于其独立,远程位置,而无需轻松访问桥接器站点的电源,极端天气条件以及桥梁与工作人员监控位置的长途通信挑战,因此为该项目选择了该项目。

The Cut River Bridge is a three span, cantilevered deck truss bridge (one of only two cantilevered deck truss bridges in Michigan), 641 feet long and containing 888 tons of structural steel, and is considered a “fracture critical” structure, which means that there is a portion of the bridge that contains a steel component whose failure could cause a portion of the bridge to collapse. After the 2007 collapse of the I-35W Bridge over the Mississippi River, fracture critical structures have received additional scrutiny in an effort to prevent a similar catastrophic event from occurring. Typically, a fracture critical structure is inspected once every two years. However, the inspection will only observe and record defects visually or through non-destructive evaluation (NDE). The actual physical stress in the structural members of the bridge is not measured and can only be observed if a member is experiencing noticeable deformation.

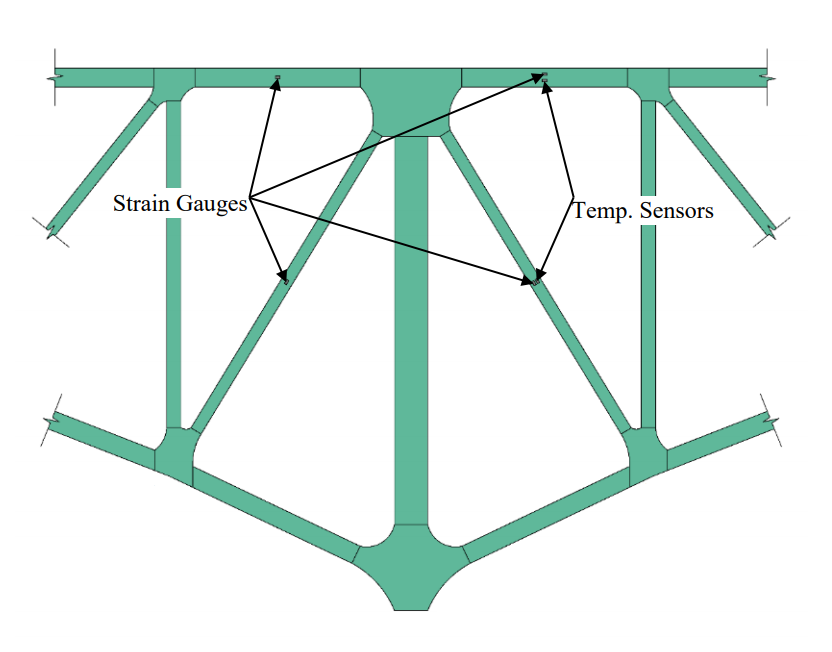

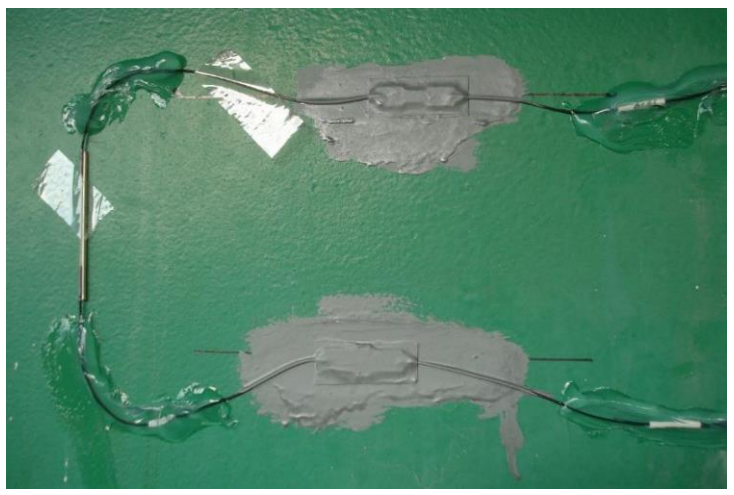

为了执行结构健康监测(SHM),在甲板桁架中的几个主要张力构件上安装了16个光纤LUNA应变仪(下面)。另外,将四个温度传感器与四个光纤应变仪中的四个相邻安装。由于温度效应,温度传感器有助于校正应变仪的任何“漂移”。为了理解穿过导致观察到的菌株的桥梁的卡车载荷,在桥梁以东大约两英里的道路下面放置了一台重型运动(WiM)站。WIM站为在高速公路上行驶的任何卡车提供轴重和间距。

MDOT选择了Luna的光纤应变仪,为传统的其他应变计类型提供的许多优点,如:更高的应变范围,较长的疲劳寿命,不受周围电磁波的影响,更快的采样率。应变读数通过温度传感器校正热效应。应变计和温度传感器设计成共同,以提供桥梁中的菌株的精确测量。

应变仪的installed at both the inside and outside faces at the north and south truss for a total of sixteen 16 locations. Temperature sensors were installed adjacent to the strain gauges only at one diagonal and one top horizontal truss member.

As light passes through the fiber optic cable and through the sensor, its wavelength changes as the strain in the Fiber Bragg Grating sensor changes and thus in the bridge member. The Luna (formerly Micron Optics) sm130 Optical Sensing Interrogator is connected to the sensors and used to continuously measure these wavelengths. It is powered by a 12V DC solar power system located in a concrete vault. The data from the interrogator is transmitted through the series of antennas and finally made available from any computer with an internet connection.

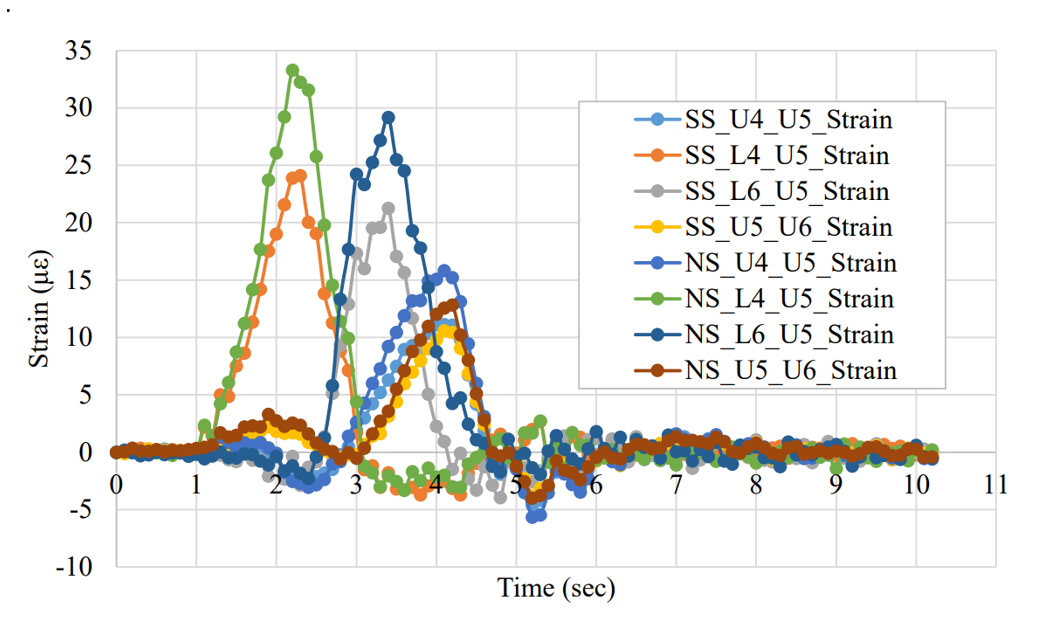

来自位于桥梁工程师办公室的计算机收集了Cut River Bridge项目的数据,但可以从带互联网接入的任何计算机收集。数据收集过程的另一个目的是获得通过这些车辆引起的桥梁以及桥梁构件中的卡车的重量和轴配置。收集数据后,处理以将卡车信息与应变信息相关联。根据当前的AASHTO和MDOT标准,该信息可用于在桥梁经历的实际负载之间进行相关性。

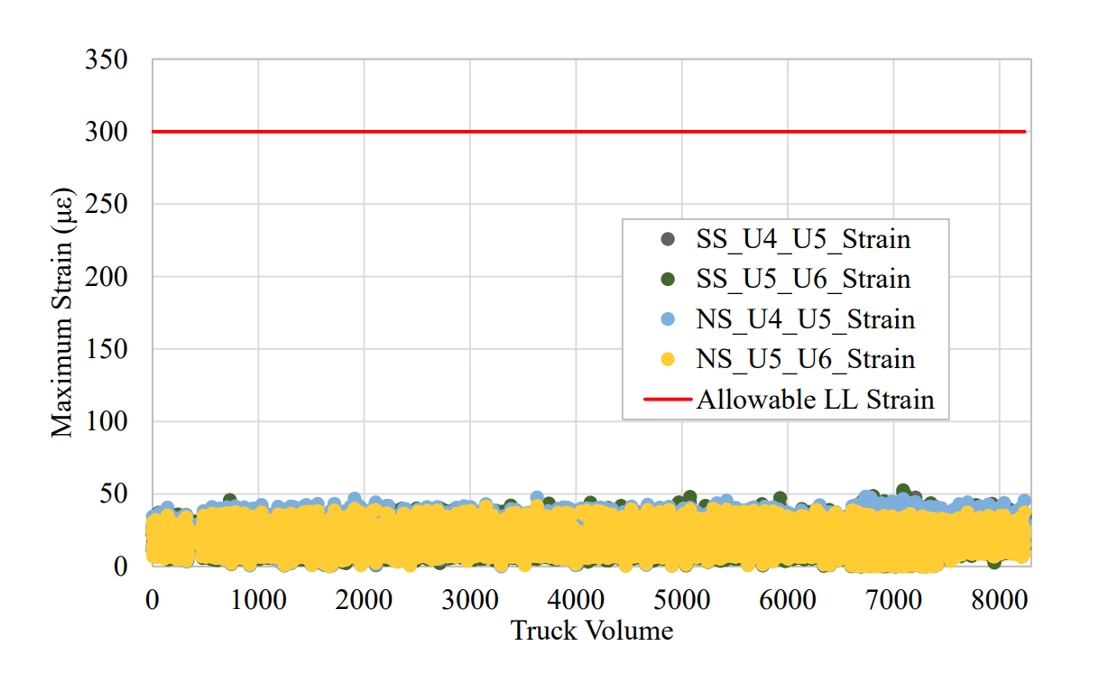

来自桥梁的应变信息用于确定由移动卡车引起的活载应变,然后与最大允许的应变进行比较,以确定桥接构件是否过度了。

The pilot project at the Cut River Bridge is a model that can be used at other bridge locations throughout Michigan. Lessons learned from this project will help MDOT with future implementations of SHM at other bridge sites.

有关Luna SM130的信息,请Hyperion Si255.询问者或者ENLIGHT software, contact us.

To read the full report by the Michigan Department of Transportation, visit这个网站.