Terametrix在Tire Tech 2019年同时展示了在线轮胎厚度和线缆平衡的同时测量188金宝慱官网

本月早些时候,Terametrix的高级研究科学家Jeffery White and Bridgestone USA的Steven Jenkins在德国汉诺威的2019年轮胎科技博览会上展示。两个演示文稿都集中在使用Terametrix的Terahertz(THz)系统同时测量总体厚度和钢或织物帘线的平衡。188金宝慱官网

本月早些时候,Terametrix的高级研究科学家Jeffery White and Bridgestone USA的Steven Jenkins在德国汉诺威的2019年轮胎科技博览会上展示。两个演示文稿都集中在使用Terametrix的Terahertz(THz)系统同时测量总体厚度和钢或织物帘线的平衡。188金宝慱官网

The installation of a TeraMetrix THz system in the Bridgestone facility in Aiken, South Carolina continues to operate well, and the Tire Tech Expo was chosen as an opportunity to present the factory results to an industry wide audience. Steven Jenkins of Bridgestone notes that the use of the scanning THz sensor has allowed plant operators to both create flatter calender sheet profiles and continuously monitor the sheet total thickness.

The current, long-existing method to measure sheet thickness is to collect a physical strip of the sheet every 1000 m of production. Five round samples are punched across this strip and weighed. These sample weights are then converted to thickness based on a previously determined calibration factor. This process is very infrequent, labor intensive and while it helps the operators stay near target thickness, the results are not timely enough to provide good control of the flatness or the thickness. The terahertz measurement is a direct measurement of thickness,rather than conversion from a mass measurement as with x-ray and nuclear sensors. It also requires no safety controls, as the THz energy is similar to far infrared light.

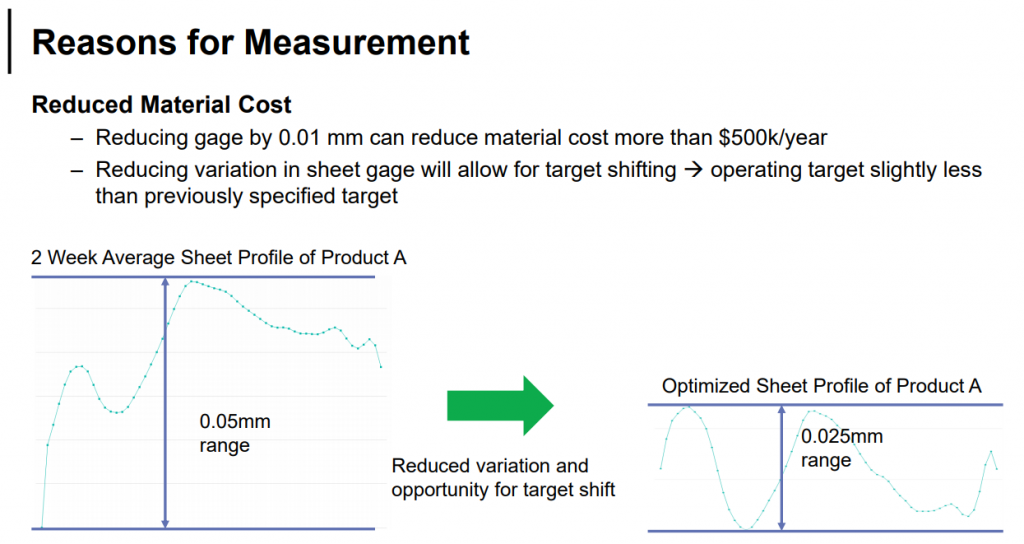

Jenkins notes that if the overall thickness of the body ply can be reduced by just 0.0004 inches (.01 mm), then savings of greater than $500,000 per year in material costs alone would be realized.

White concentrated his presentation on the measurement of the “Balance” of the cords with the ply. Balance is a measure of the vertical position of the cords within the ply. Typically, the cords should be centered, top to bottom, but there are cases when the cords are purposefully offset. The balance measurement is extremely important for the safety of the tire. If the balance changes within the ply, especially if balance varies significantly on opposite sides of the tire, then vibration and friction forces will occur within the tire, potentially leading to catastrophic failure.

星座is the only measurement method that has demonstrated direct, real-time measurement of the balance of fabric cord ply products. This is accomplished by measuring the TIME between reflections off interfaces in the corded body ply. The TeraMetrix system also has the ability to perform an on-demand, in-production material property check to ensure the THz measurement remains accurate, especially through material batch changes, shift changes, production stops / restarts and new product starts.

星座is the only measurement method that has demonstrated direct, real-time measurement of the balance of fabric cord ply products. This is accomplished by measuring the TIME between reflections off interfaces in the corded body ply. The TeraMetrix system also has the ability to perform an on-demand, in-production material property check to ensure the THz measurement remains accurate, especially through material batch changes, shift changes, production stops / restarts and new product starts.

After successful presentations on the first day of the event, representatives from nearly every major western tire manufacturing company stopped by the exposition booth for further discussions and to see a demo of how the THz sensor is able to provide an immediate measurement of two-layer extrusions samples. TeraMetrix is able to supply a solution to a current issue (balance measurement of fabric corded products), an improved measurement, leading to huge cost savings (optimum total ply thickness).

会议还允许Terametrix从制造商那样喜欢分层检测和线间距测量等制造商的其他未满足的测量需求。此外,一些制造商对多层挤出材料产品(未固化橡胶组件)感兴趣。188金宝慱欢迎你总体而言,会议是取得成功的成功,允许Terametrix在制造过程中分享THz测量的益处,并与行业领导者达到更好地了解其制造需求。

To review both Tire Tech presentations and learn more how TeraMetrix THz measurement systems can help your manufacturing process, please see the links below:

Steven Jenkins (Bridgestone USA) Tire Tech 2019 Presentation